Servo Screw Air Compressors

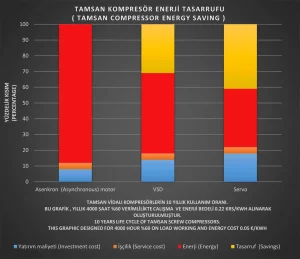

The key advantage of servo screw air compressors is their significant energy savings, ranging between 20% and 50% compared to traditional fixed star-delta rotary screw compressors. Additionally, they provide 8% to 10% extra energy savings over standard VSD (Variable Speed Drive) compressors. Traditional VSD compressors use asynchronous motors with 88% to 90% efficiency, whereas Servo Series compressors operate with synchronous motors that achieve up to 96% efficiency, making them First Class energy-saving motors.

Integrated High-Efficiency Design

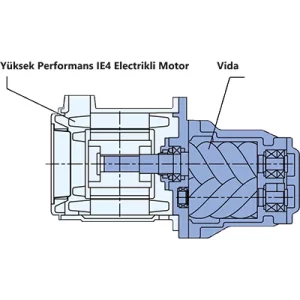

Pertofeb Services’ Servo Screw Compressors feature a compact and space-saving structure, integrating the screw unit with a high-efficiency synchronous motor.

Featured Features

✅ High Energy Efficiency – Synchronous servo motors operate at up to 96% efficiency, reducing energy consumption and offering additional 8% to 10% savings over standard VSD compressors.

✅ Compact & Durable Design – The integrated screw unit and synchronous motor ensure a space-saving, efficient design, with optimized magnetic field distribution.

✅ Intelligent Control System – The air control capacity and system temperature are automatically adjusted, ensuring stable operation and easy control.

✅ Easy Maintenance – The servo motor is one-third the size of a traditional synchronous motor, making maintenance simple and efficient.

Technical Specifications

| Models & Technical Specifications | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Free air measurements at the specified pressures were determined according to ISO 1217 Annex C Standards. The specified flow values are values obtained at 7 bar(g) pressure. | ||||||||||||

| Model | Working Pressure | TVK 1901 Servo | TVK 2501 Servo | TVK 3801 Servo | TVK 5201 Servo | TVK 6400 Servo | TVK 7800 Servo | TVK 9800 Servo | TVK 12600 Servo | TVK 15800 Servo | TVK 18700 Servo | TVK 23100 Servo |

| Capacity (m³/min) | 5-10 bars(g) | 0.7 – 2.0 | 0.95 – 2.70 | 1.35 – 3.95 | 1.95 – 5.55 | 2.40 – 6.90 | 2.95 – 8.45 | 3.65 – 10.50 | 5.00 – 14.35 | 6.25 – 18.05 | 7.8 – 22.90 | 9.35 – 26.8 |

| Ambient Temperature (°C) | – | 2 – 40 | 2 – 40 | 2 – 40 | 2 – 40 | 2 – 40 | 2 – 40 | 2 – 40 | 2 – 40 | 2 – 40 | 2 – 40 | 2 – 40 |

| Cooling | – | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling |

| Outlet Temperature (°C) | – | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 | Ambient Temperature + 10 |

| Sound Level (dB(A)) | – | ~ 71 | ~ 71 | ~ 75 | ~ 75 | ~ 75 | ~ 75 | ~ 75 | ~ 75 | ~ 80 | ~ 80 | ~ 80 |

| Engine Drive Mode | – | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed | Inverter Controlled Variable Speed |

| Strength | – | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph | 400V 50Hz 3ph |

| Engine Power (kW) | – | 15 | 20 | 30 | 40 | 50 | 60 | 75 | 100 | 125 | 150 | 180 |

| Takeoff Mode | – | VSD | VSD | VSD | VSD | VSD | VSD | VSD | VSD | VSD | VSD | VSD |